Executive Summary

A leading North American electronics manufacturing platform provider faced challenges in its PCB inspection process due to heavy reliance on manual labor. To overcome this, they partnered with Elastiq and Google Cloud and implemented a cutting-edge Computer Vision solution powered by AI.

The AI-driven system achieved a remarkable 99.8% precision as well as recall in inspecting whether a component is present or absent from the cropped image of a PCB. This accelerated the Quality Assurance (QA) process time by 100x and delivered 10x cost savings

Client Profile

The client, a pioneer in the electronics manufacturing industry, has built a tech platform that helps create, automate, and optimize the electronic manufacturing process. They inspect millions of chips in a year and sought to enhance their quality control processes by incorporating AI to improve defect detection and overall efficiency.

Business Challenges

The client’s chip inspection process was characterized by several critical issues:

- Manual Labor-Intensive Tasks: Inspections were performed manually, leading to inconsistent results and worker fatigue.

- Inability to Scale: As production demands increased, the existing process couldn’t keep pace, creating bottlenecks.

- Delayed Time-to-Market: The slow inspection process extended production cycles by days together per batch.

Furthermore, due to the manual nature of the inspection process, the manufacturer was only able to spot check a portion of each batch, instead of testing each PCB.

Elastiq Solution

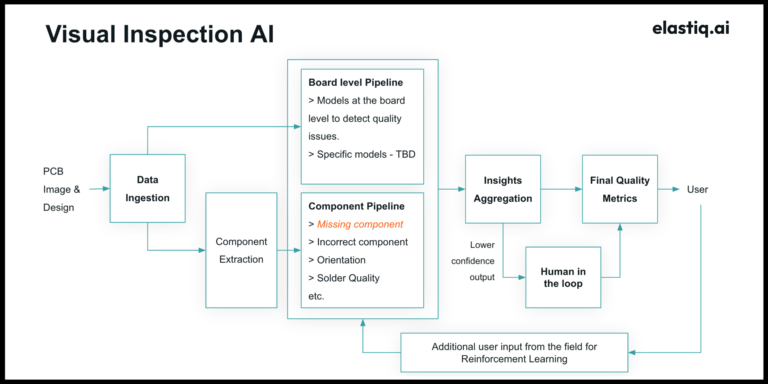

Elastiq partnered with Google Cloud to develop a customized Computer Vision solution tailored to the client’s PCB inspection workflow. The solution leveraged custom computer vision models built on Google Cloud Vertex AI to accurately identify missing components on each circuit board. The solution consisted of:

- Data Ingestion Pipeline: Efficiently collecting and preparing PCB image data for analysis.

- AI Models: Computer vision models that accurately identified missing components in PCBs.

We employed Google Cloud’s robust infrastructure for efficient data handling and model development. PCB images were organized into dedicated folders in buckets on Cloud Storage, labeled as ‘missing’ or ‘present’ for supervised learning. Vertex AI’s AutoML capabilities were leveraged to train a custom computer vision model, using the labeled dataset.

Its performance was rigorously evaluated using metrics like precision and recall. Once optimized, the trained model was deployed to a cloud-based endpoint for real-time predictions, ensuring scalable and reliable PCB inspection.

Result & Impact

The implementation of Elastiq’s Computer Vision solution yielded impressive results:

- Unprecedented Accuracy: Achieved a 99.8% precision and recall in defect detection, significantly reducing the incidence of missed or misidentified defects.

- Accelerated QA Process: Increased inspection speed by 100x, enabling faster turnaround times and increased throughput.

- Significant Cost Savings: Reduced manual inspections and rework, leading to 10x cost savings.

What impressed the client most was Elastiq’s end-to-end capabilities, encompassing model development and deployment, all while leveraging Google Cloud’s scalable and robust infrastructure.

Conclusion

The partnership between Elastiq and the electronics manufacturer demonstrates the power of AI in transforming complex business processes. The Google Cloud powered AI-driven system achieved a remarkable 99.8% accuracy in component detection, while also accelerating the QA process by 100x and reducing costs by 10x.

By overcoming the limitations of traditional manual inspection methods, the client was able to enhance their operational efficiency, reduce costs, and improve customer satisfaction.